Glue Guns to the Rescue

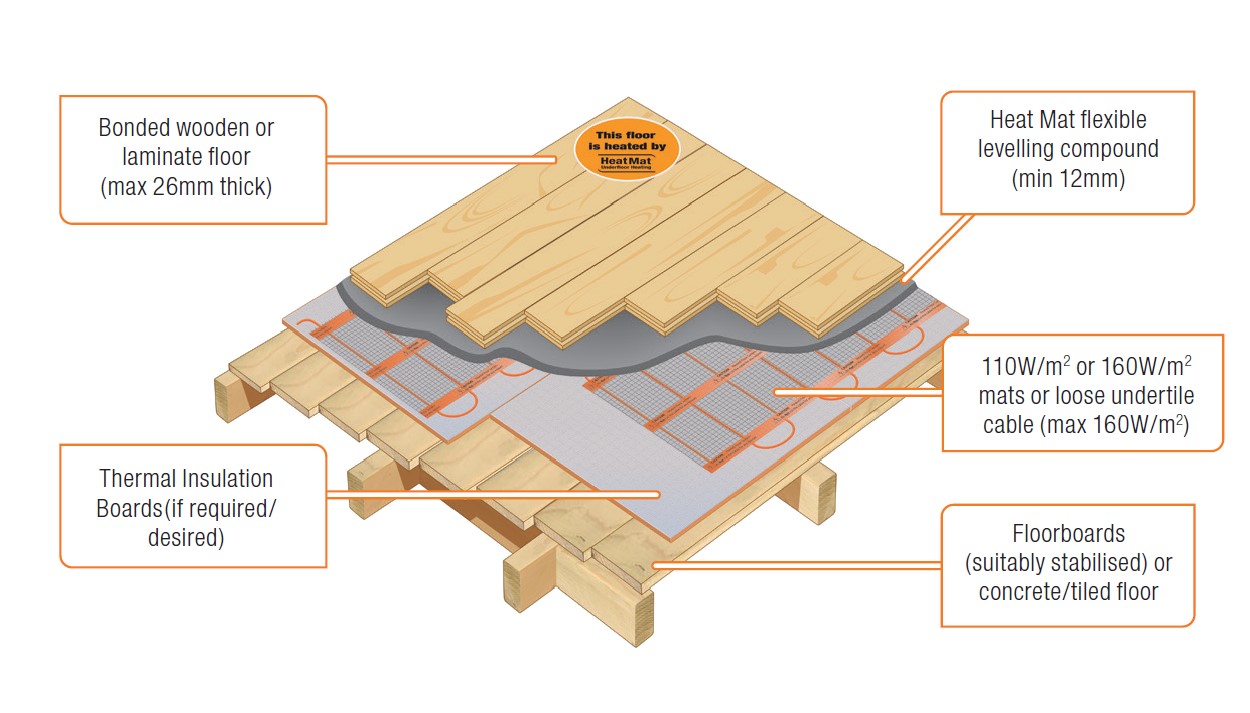

Over the weekend I was helping some friends install their underfloor heating system prior to the floor covering installer coming to pour the levelling compound and lay the vinyl later this week. They had already installed the thermal insulation boards themselves, so it was simply a question of sketching out where the underfloor heating mats should go, cutting and turning the mats as required and then peeling off the backing on the double-sided sticky tape to affix them to the floor surface.

Once we had completed the installation we had a cup of tea and sat back and admired our handy work, and it was at that point that I thought ahead to the levelling compound being poured later this week.

Regardless of how well the double sided tape sticks down the heating mats, once the levelling compound is poured some small bits of the fibreglass mesh always 'float' to the surface of the compound. These have to be removed with sandpaper once the compound is dry to ensure they do not effect the final floor finish and although this doesn't take long to do, its great to avoid this problem all together.

Over the years our technical team has looked at various options for avoiding this issue with the design of our mats, however the only solutions we came up with had issues of their own. The first solution was to make the fibre-glass mesh significantly heavier so it would not float up in the compound, but this led to more unwieldy mats and the mesh was significantly harder to cut.

The alternative was to use mats which had a spray glue on their back to ensure that all of the mesh stuck down to the floor. Although this worked well in laboratory conditions, out in the real world on site mats will often be moved backwards and forwards before their final position is chosen. The constant handling of the sticky mats left our hands (and any of the tools or surfaces we touched) covered in glue, and in dusty conditions the adhesive soon became useless.

So, the solution didn't appear to be one of redesigning the heating mat, but rather finding an alternative way to stick down the mesh. After a small amount of testing, we found that the fastest and most reliable method was simply to use a hot glue gun. It takes roughly a minute for each square metre of heating mat and when you have finished the mesh wont be going anywhere!

So, going back to this weekend, after finishing my tea I grabbed my hot glue gun and got to work wiping a small amount of glue along the very edge of the mesh on each of the heating mats. Quarter of an hour later the entire heating system was finished, and I had also used the glue gun to stick down any sections of heating cable that could possible be caught when the installers come back later in the week to lay the levelling compound.

The result; a great looking underfloor heating system that is very difficult for any trades-person to catch their foot on as they walk above it, and when the levelling compound is poured the mesh will stay exactly where it is without any floating to the surface.

Although its not essential to use a glue gun to secure the edges of the mesh, for anyone pouring a levelling compound on top of their underfloor heating mats it is well worth considering, and takes very little time to do. The only thing to be cautious about is to ensure that you don't rest the tip of your glue gun on the heating cable for more than a split-second in case it damaged the outer insulation.]